Main Blog

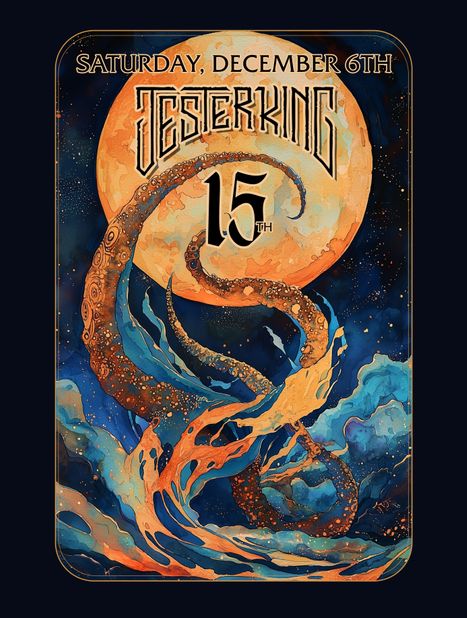

15th Anniversary Party Final Details!

Our 15th anniversary party is this Saturday, December 6th! Free. All ages.

Boy do we have a great day planned full of music, food, drink, holiday shopping, panels, activities, and events all centered around a celebration of fermentation and funk! We hope to see you Saturday! The weather is looking great too ;)

🎸 𝐌𝐔𝐒𝐈𝐂

12-2pm — Moving Blues @movingblues

2-4pm — Rippleberry @rippleberryband

4:45-6:15pm — The Peterson Brothers @thepetersonbrothers

more15th Anniversary Party Guest Beer Lineup

For our 15th anniversary on Saturday, December 6th, we’re very lucky and excited to be pouring beers from some of the best farmhouse and wild ale producers in America. Having our beer poured side by side with these small, artisanal brewers will make it a special commemoration of Jester King’s 15 years.

𝐀𝐌𝐄𝐑𝐈𝐂𝐀𝐍 𝐒𝐎𝐋𝐄𝐑𝐀 𝐁𝐑𝐄𝐖𝐄𝐑𝐘

Petit Cochon — Sour Ale Aged in Oak Tanks With Montmorency Cherries

𝐀𝐋𝐋𝐀𝐆𝐀𝐒𝐇 𝐁𝐑𝐄𝐖𝐈𝐍𝐆 𝐂𝐎.

Coolship Resurgam — Three year blend of spontaneous beer

Once Upon an Orchard — Wild Saison blend on Paw Paw Fruit

Means and Strategy — Foudre-aged wild blonde ale w/ muscadine grapes

𝐅𝐀𝐈𝐑 𝐈𝐒𝐋𝐄 𝐁𝐑𝐄𝐖𝐈𝐍𝐆

Hima — saison refermented with caramelized quince

𝐅𝐎𝐍𝐓𝐀 𝐅𝐋𝐎𝐑𝐀 𝐁𝐑𝐄𝐖𝐄𝐑𝐘

Estate Saison 2025 — seashore black rye, hopi black dye sunflowers and seeds, safari tangerine marigold flowers, and lemon basil

𝐆𝐀𝐑𝐃𝐄𝐍 𝐏𝐀𝐓𝐇 𝐅𝐄𝐑𝐌𝐄𝐍𝐓𝐀𝐓𝐈𝐎𝐍

The Spontaneous Ferment 5-Year Anniversary

The Little Horse Around — oak-fermented table beer

𝐇𝐈𝐋𝐋 𝐅𝐀𝐑𝐌𝐒𝐓𝐄𝐀𝐃 𝐁𝐑𝐄𝐖𝐄𝐑𝐘

Anna Farmstead® Ale — Vermont wildflower honey, farmhouse yeast, well water

more2025 Funk n' Sour Fest

Funk n’ Sour 2025 at Jester King Brewery

📅 Thursday, October 23 | ⏰ 6:00–10:00 PM | 📍 Jester King Brewery

Please join us for a flavorful evening celebrating the art of food and beverage pairing at Jester King’s annual Funk n’ Sour.

Guests will enjoy 25 thoughtfully curated pairings presented by Austin’s leading restaurants in collaboration with world-class breweries, wineries, cideries, and distilleries. The evening begins at 6:00 PM with a welcome pour from Jester King, followed by unlimited access to food and drink tastings from 7:00 PM onward. Each ticket includes all pairings, a welcome pour, and commemorative Funk n’ Sour 2025 glassware.

Tickets:

Regular -- $160

VIP (30-minute early entry) -- $185

Here's the list of our restaurants and pairings for 2025!

Abby Jane Bakeshop x NICE N EASY

Better Half x La Cruz de Comal Wines

Bufalina x Crowson Wines

Casa Bianca x Revolution Spirits

Dai Due x Zilker Brewing Co.

Dovetail Pizza x Oddwood Brewing Co.

El Raval x Balcones Distilling

Foreign & Domestic x Real Ale

Interstellar BBQ x Jester King Brewery

Jester King Kitchen x The Brewtorium

moreCrosby Fresh Hopped Pilsner

We're happy to release our second of two fresh hop beers this year -- Crosby Fresh Hopped Pilsner!

Crosby Fresh Hopped Pilsner is a 100% fresh hop beer brewed with freshly harvested Strata from @crosbyhops, then dry hopped with Crosby Amarillo CGX fresh hops!

In late August, we received 240 pounds of freshly picked Strata that were harvested and shipped overnight to Jester King. The Strata arrived in absolutely beautiful shape thanks to the excellent work of the team at Crosby in Oregon. The fresh Strata was bursting with bright notes of strawberry and citrus. We brewed a pale lager wort and converted our coolship into a giant hopback for the Strata. We then whirlpool with more fresh hop Strata.

After primary fermentation with lager yeast, we added Crosby Amarillo CGX fresh hops as a "wet hop, dry hop." We'd never had the experience of adding fresh hops on the cold side, so this was a lot of fun for us to try!

After another six weeks of patient refinement through lagering, we packaged Crosby Fresh Hopped Pilsner into kegs and cans, which we've begun self-distributing around Texas! Look for it at a location near you in Texas, or find some at Jester King open 7 days a week!

more2024 Funk n' Sour Fest Pairings Announced!

Here are the 50 amazing, insane pairings for Funk n' Sour Fest on October 29th! This is truly one of kind. You don't want to miss this event!

Abby Jane Bake Shop / Acopon Brewing

1. Red Fife sourdough & butter made from a single variety wheat paired with Baecere ESB (made with bread from Abby Jane)

2. Ras al Hanout spice cake filled with apple butter and caramel buttercream paired with Efnwyrcing Coffee Milk Stout brewed with Rouge de Bordeaux wheat from Barton springs mill, and Weathered Hands coffee beans aged in bourbon barrels

Better Half / Balcones Distilling

1. Pork Ribs mirador braise, fish caramel, pork fat garlic paired with Mirador Eclipse Single Malt

2. White Sangria cocktail Sweet Potato Moon Pie paired with Mirador Marshmallow Fluff paired with Mirador Eclipse Single Malt Neat

Bufalina / Live Oak Brewing

more2024 Funk n' Sour Fest!

Jester King Funk n' Sour Fest is returning at 7pm on October 29th for another amazing installment! In what has evolved over the last decade into our signature event, Funk n' Sour Fest features some of the best restaurants in Austin paired with some of the best breweries, wineries, cideries, and distilleries in Texas!

This year, we've grown Funk n' Sour to partner twenty-five restaurants with twenty-five beer/wine/cider/spirit producers to create fifty different pairings!

Such an awesome collaborative display of talent will undoubtedly create memorable pairings and a magical evening. If you've been to Funk n' Sour before, you know this is not an event to miss!

2024 partners are listed below.

Odd Duck x Nice n' Easy

Sour Duck x Pinthouse Brewing

Emmer & Rye x Still Austin

Jester King Kitchen x Texas Keeper Cider

LeRoy & Lewis x Jester King Brewery

Fella x Texas Sake Co.

Olamaie x St. Elmo Brewing Co.

Better Half x Balcones Distilling

Dai Due x Hold Out Brewing

more14th Anniversary Lager Fest!

Jester King is turning 14! To celebrate, we're hosting an epic lager fest with 24 awesome breweries! In addition to food trucks, live music, face painting, coffee, artisan vedors, and more, we'll have this incredible beer list.

Get your ticket today!

𝐅𝐢𝐯𝐞 𝐒𝐭𝐨𝐧𝐞𝐬 𝐀𝐫𝐭𝐢𝐬𝐚𝐧 𝐁𝐫𝐞𝐰𝐞𝐫𝐲

Uncle Mick’s American Red Lager

Braunfelser Festbier

𝐂𝐞𝐥𝐢𝐬 𝐁𝐫𝐞𝐰𝐞𝐫𝐲

Celis Pony Boy Light Lager

𝐂𝐞𝐧𝐭𝐫𝐚𝐥 𝐌𝐚𝐜𝐡𝐢𝐧𝐞 𝐖𝐨𝐫𝐤𝐬

Pilsner

American Lager

𝐅𝐚𝐦𝐢𝐥𝐲 𝐁𝐮𝐬𝐢𝐧𝐞𝐬𝐬 𝐁𝐞𝐞𝐫 𝐂𝐨.

Family Business Spacious Skies

Golden Age

𝐅𝐚𝐬𝐭 𝐅𝐫𝐢𝐞𝐧𝐝𝐬 𝐁𝐞𝐞𝐫 𝐂𝐨.

Luker Czech Pilsner

Festbier

𝐅𝐢𝐭𝐳𝐡𝐮𝐠𝐡 𝐁𝐫𝐞𝐰𝐢𝐧𝐠

Fitz Lite American Lite Lager

Brazilian Kasiri Cassava root lager

𝐆𝐡𝐨𝐬𝐭 𝐍𝐨𝐭𝐞 𝐁𝐫𝐞𝐰𝐢𝐧𝐠

Painted Porch Pilsner

𝐇𝐨𝐥𝐝 𝐎𝐮𝐭 𝐁𝐫𝐞𝐰𝐢𝐧𝐠

Neu! Pils

Lagerface Smoked Pale Lager

𝐈𝐧𝐝𝐞𝐩𝐞𝐧𝐝𝐞𝐧𝐜𝐞 𝐁𝐫𝐞𝐰𝐢𝐧𝐠 𝐂𝐨.

TBD

𝐉𝐞𝐬𝐭𝐞𝐫 𝐊𝐢𝐧𝐠 𝐁𝐫𝐞𝐰𝐞𝐫𝐲

moreLabor Day Weekend at Jester King

𝐋𝐀𝐁𝐎𝐑 𝐃𝐀𝐘 𝐖𝐄𝐄𝐊𝐄𝐍𝐃 𝐀𝐓 𝐉𝐄𝐒𝐓𝐄𝐑 𝐊𝐈𝐍𝐆

𝐄𝐗𝐓𝐄𝐍𝐃𝐄𝐃 𝐇𝐎𝐔𝐑𝐒

Friday 2-9

Saturday 11-9

Sunday 11-9

Monday 11-8

𝐀𝐔𝐒𝐓𝐈𝐍 𝐅𝐋𝐄𝐀

Handmade, Vintage, Local

Saturday 11-3pm

𝐋𝐈𝐕𝐄 𝐌𝐔𝐒𝐈𝐂

Friday, 8/30 from 6-8 pm — Strawberry Flats

Saturday, 8/31 from 1-3pm — Deer Fellow

Saturday, 8/31 from 6-8pm — Dustin Brown

Sunday, 9/1 from 1-3pm — Julia Rose

Sunday, 9/1 from 5-8pm — Bluegrass Pals

Monday, 9/2 from 1-4pm — White Haired Kids

𝐆𝐎𝐀𝐓 𝐄𝐕𝐄𝐓𝐒

Guided Goat Walks — Wednesday, Thursday, and Friday at 7pm

https://jesterkingbrewery.com/tours.../guided-goat-walk...

more💧🛝🍦 SIP N’ SLIP FAMILY FUN WEEKEND! 😎🍹💧post

Join us the weekend of August, 23rd to 25th at Jester King for summer fun for the whole family! Enjoy craft ice cream and sorbet push pops from Flight Ice Creams @flighticecreams and Beanz Creamz @beanz.creamz, New Orleans Style Shaved Ice from @snoasisdstx, a plant workshop by Austin’s Leaf Lovers Club @leafloversclub, mosaic making by The Art Garage @theartgarage_atx theartgarage_atx, face painting by @zirenart_ig, live music, and a water slide for the kids! Don’t miss out on this one!

more4th of July Week at Jester King

We have loads of fun stuff in store at Jester King the week of the 4th!

🎵 𝐋𝐈𝐕𝐄 𝐌𝐔𝐒𝐈𝐂 🎸

July 4th, 1-4pm -- Torin Franklin @torin_franklin

July 4th, 5-8pm -- The Rhinestone Renegades 5-8pm! @rhinestone_renegades

July 5th, 6-10pm -- The Band of Heathens with special guest Jamie Lin Wilson (𝑻𝑰𝑪𝑲𝑬𝑻𝑬𝑫 𝑺𝑯𝑶𝑾: https://www.exploretock.com/jesterkingbrewery/event/483460/the-band-of-heathens-at-jester-king-brewery) @bandofheathens @jamielinwilson

July 6th, 1-3pm -- Torin Franklin @torin_franklin

July 6th, 4-6pm -- Lauren Diamond @laurendiamondmusic

July 7th, 1-4pm -- Bluegrass Pals @bluegrasspals

💧 𝐒𝐋𝐈𝐏 𝐍' 𝐒𝐋𝐈𝐃𝐄 💧

We'll have an inflatable water slide going in our pasture all holiday weekend from Thursday the 4th to Sunday the 7th!

🍕 𝐅𝐎𝐎𝐃 🍔

❄️ SNOasis New Orleans Style Shaved Ice Friday to Sunday @snoasisdstx

🌭 Zee's Wiener System Friday during The Band of Heathens @wienersystem

🍕 Firecracker Pizza from Jester King -- Adagio Bomba salami, bechamel, Lioni mozzarella, cherry tomatoes, calabrian chilies, hot honey, Keaglewicz Farms lemon basil micro greens

moreMemorial Day Weekend at Jester King

We have an exciting Memorial Day weekend planned at Jester King! Join us for great food, drink, live music, and artisan goods on our beautiful ranch on the outskirts of Austin! Details below.

𝐋𝐈𝐕𝐄 𝐌𝐔𝐒𝐈𝐂 𝐋𝐈𝐍𝐄𝐔𝐏

Saturday 12-3pm -- Moving Blues @movingblues

Saturday 4-6pm -- Torin Franklin @torin_franklin

Sunday 1-4pm -- Western Union Man @western_union_man

Sunday 5-8pm -- Matagorda @matagora

Monday 1-4pm -- Bluegrass Pals @bluegrasspals

Monday 5-8pm -- Brodie Lane @brodielanetx

𝐌𝐈𝐋𝐈𝐓𝐀𝐑𝐘 𝐃𝐈𝐒𝐂𝐎𝐔𝐍𝐓

All active duty military receive 20% off all weekend

𝐌𝐄𝐌𝐎𝐑𝐈𝐀𝐋 𝐃𝐀𝐘 𝐕𝐄𝐍𝐃𝐎𝐑𝐒

On Monday we're hosting:

Flowers from Nutty Brown Farm @nutty_brown_farm

Never Knew Us Vintage @neverknewus

Curios Candle Works @curioscandleworks

𝐍𝐄𝐖 𝐏𝐈𝐙𝐙𝐀

The Iberian — Adagio Chorizo, sage oil, Lioneli mozzarella, manchego, red onions, charred corn relish, lime crema, Keaglewicz Farms micro cilantro

𝐏𝐔𝐄𝐍𝐓𝐄 𝐂𝐎𝐅𝐅𝐄𝐄 𝐂𝐎.

At Jester King Memorial Day from 11-4pm on Memorial Day! @puentecoffeeco

𝐋𝐀𝐒𝐓 𝐒𝐀𝐓𝐔𝐑𝐃𝐀𝐘 𝐅𝐎𝐑 𝐃𝐎𝐎𝐌 𝐌𝐄𝐓𝐀𝐋 𝐆𝐎𝐀𝐓 𝐘𝐎𝐆𝐀!

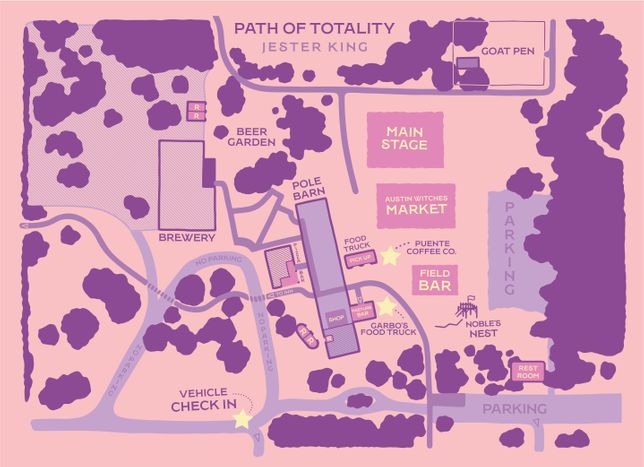

morePath Of Totality At Jester King Final Details!

Parking lots open at 8am! Please allow plenty of time to arrive Monday in case traffic is heavy. Puente Coffee Co. will start serving at 9am and Jester King will open at 10am. Please have your parking pass QR code ready for our attendants when you arrive. @puentecoffeeco

moreDoom Forge Day 2024

Here's the rundown of event times for Doom Forge Day this Sunday!

11am to 9pm -- OPEN. FREE ENTRANCE. ALL AGES.

All Day -- Texas Viking Invasion (Pasture)

All Day -- Live blade smithing with Fearghal Blades & Angel Sword (Pole Barn & Beer Garden)

All Day -- Figure 8 Coffee (Beer Garden)

11am to out -- Specialty guest beers on tap (Beer Garden)

11am to sold out -- Pastrami Smash Burger (Beer Garden)

12pm to 3pm -- Battle Vest Goat Photos (Goat Barn)

11am to 4pm -- Corpse Paint Booth (Pole Barn)

11am to 5pm -- Live Tattooing (Brewery)

11am to 5:30pm -- Austin Flea (Pole Barn)

12:15pm to 1pm -- Stout & Pastry Pairing with Marcus Baskerville of Weathered Souls (Jester King Hall)

1pm -- Founder's Tour with Jeffrey Stuffings (Brewery)

moreDOOM FORGE DAY BEER LIST!!!

Here's our specialty list of beers for DOOM FORGE DAY this Sunday, January 21st!

Jester King Doom Forge Imperial Coffee Stout

Jester King Whiskey Barrel Rodeo

Jester King Black Atrial

Jester King Maple Bourbon Barrel Aged Black Atrial

Jester King Bourbon Barrel Aged Vanilla Black Metal

Jester King Black is Beautiful

Jester King Black Metal

Jester King Funk Metal

(512) Whiskey Barrel Aged Double Pecan Porter

American Solera Fat Camp

Fonta Flora Oyster Stout

Fonta Flora Steinbock

Hold Out - East of Sweden Baltic Porter (collab with Fast Friends)

Real Ale - Commissar Russian Imperial Stout

St. Elmo - 4th Anniversary Balcones Bourbon Barrel-Aged Imperial Stout

Weathered Souls Toasted Tracks

Weathered Souls TBD

In addition to this list, we'll have several other Jester King lagers, farmhouse ales, IPAs, fruited wild, and SPON including:

German-Style Pilsner

Staked Plains Pilsner

Nani?! Japanese-Style Rice Lager

Munich-Style Helles Lager

Moderne Dansk

Demitone

Nocturn Chrysalis

Balcones Barrel Aged Moderne Dansk

2023 Hibernal Dichotomous

moreBlack Friday Cellar Release

It's that time of year again that we break out some dusty old bottles from our cellar! Black Friday we'll be releasing the following bottles from our cellar starting at 11am when we open.

The bottles span a decade of experimentation, creativity, and commitment to artisan brewing principles and wild fermentation. We hope you enjoy these rare treats.

First come first serve. Limit one bottle per beer, but otherwise no limits.

2016 SPON Methode Gueuze 750ml x 1 ($45)

Tulle 750ml x 1 ($30)

2016 SPON Flor 375ml x 2 ($30)

2016 SPON Peach & Apricot 375ml x 3 ($25)

2017 SPON Peach & Apricot 375ml x 3 ($25)

SPON 13th Anniversary Blend 750mml x 3 ($25)

2021 Balcones Texas Single Malt Whiskey Barrel-aged SPON 375ml x 3 ($22)

2019 SPON Cab Franc & Zinfandel 375ml x 4 ($22)

Coolship Roadtrip 375ml x 4 ($22)

2018 SPON Grapefruit 750ml x 3 ($28)

2018 SPON Muscat 375ml x 4 ($22)

2018 SPON Three Year Blend 750ml x 3 ($36)

2021 SPON Chenin Blanc 750ml x 3 ($30)

2021 SPON Prickly Pear 375ml x 3 ($22)

2021 SPON Blueberry & Pitaya 375ml x 4 ($22)

2021 SPON Rye 750ml x 3 ($30)

moreQR Code Ordering is Back

We're happy to announce that QR code ordering is back at Jester King. Starting this Friday, our guests can order food and drink at any bar or QR code. It's that simple. Order whatever you'd like in person or from any QR code on our ranch.

We started QR code ordering back in 2020, which helped shorten lines. People seemed to like them. We understand that people come out to Jester King to enjoy great pizza and beer in a beautiful place while getting to spend disconnected, quality time with friends and family. We care deeply about our food and beer, but we see helping create enjoyable, disconnected time with friends and family as our core purpose for existing. Waiting in line too much obviously defeats all that. With QR codes, even if we're very busy on a beautiful Saturday afternoon and pizza times are long, at least folks can get a quick beer and enjoy the company of their friends from their table instead of waiting in line to order.

Why did we move away from QR codes earlier this year? We don't love the impersonal nature of them and having to interface with a device. Service and hospitality are important to us, and a lot of love goes into our food and beer, so we felt the Jester King experience was suffering due to the lack of personal connection. But like most things, one extreme or the other isn't great, and we're back with a hybrid — order at any bar in person or by QR code.

moreJester King Self-Distribution is Back!

We're very excited to announce that Jester King will soon self-distribute our beer in parts of Texas! Starting next month, we'll be self-distributing kegs and cans of our lagers, IPAs, farmhouse ales, and fruit beers to select accounts.

If you're with a Texas bar, restaurant, or store interested in selling Jester King, please hit us up at 512-468-4646 or beer@jesterkingbrewery.com.

moreOH! - An Otoko Collaboration Beer

We're honored, excited, and grateful to announce the release of OH! — farmhouse ale with Sansho pepper brewed in collaboration with Chef Yoshi Okai of Otoko in Austin.

We've been enormous fans of Chef Yoshi for the last several years. His culinary combination of restraint, subtlety, artistry, and creativity is very special, and he's a really friendly, down to Earth person on top of it.

For OH!, we felt a duty to create flavors and harmony that would meld with his cuisine. To this end, we took Chef Yoshi up on his suggestion to use Sansho pepper, a common element in his cooking. From there, brewing and achieving balance with OH! was an exercise in restraint. We were tempted at multiple points throughout the creative and brewing process to add more ingredients and boldness of flavors. But in the end, throughout several test blends, we found a beer we believe beautifully integrates fermentation character, crisp Texas malt flavor, and a subtle floral/fruit character from the Sansho pepper. We're proud and excited to see OH! paired alongside Chef Yoshi's outstanding cuisine at Otoko!

Apart from Otoko, be on the lookout for OH! at Jester King and in some places abroad given limited distribution. Finally, a special thank you to Chef Yoshi and his team at Otoko for the opportunity to collaborate with them. They curate a special experience and are even better people!

moreGrim Harvest

Our 2023 batch of Grim Harvest — farmhouse ale with blackberries — is now available at Jester King.

For Grim Harvest, we brew fresh wort with Hill Country well water, west Texas barley and wheat from TexMalt, fresh and aged hops, then ferment it on the blackberries from Nocturn Chrysalis (barrel-aged wild ale with blackberries). This second "maceration" of the fruit yields a more subtle fruit character, with elements of the base beer coming through more prominently. This blackberry farmhouse ale is mildly tart, effervescent from bottle conditioning, and has a present but restrained fruit character. It's an authentic representation of Texas farmhouse ale tied to time, place, and people.

Grim Harvest will be available onsite and online starting 5/12. Shipping/delivery illegal in Texas.

Artwork by Joshua Cockrell. Photo by Regan Vaca.

moreModerne Dansk

We're releasing our 4th batch of Moderne Dansk!Moderne Dansk is our barrel-aged wild ale refermented with Danish Stevnsbær cherry juice from Frederiksdal Kirsebærvin in Denmark.

The character of the Stevnsbær cherries is one of our favorite sensory experiences. The aroma is almost unreal. We created a nice, soft blend of pale/golden wild ale aged in oak barrels for about a year, then re-fermented the cherry juice with the beer to complete dryness. The interplay between Hill Country well water, Texas grain, aged hops, native yeast, and Stevnsbær cherry juice creates a beer that's highly unique to the terroir of Texas and Denmark.

Modern Danske will be available onsite and online starting 5/4. Shipping/delivery illegal in Texas.

Artwork by Joshua Cockrell. Photo by Regan Vaca.

moreReturn to In-Person Ordering

We're excited to announce that as of this week, we're fully back to in-person ordering of food and drink at Jester King. This is the way it was at Jester King from 2011 to 2020, and we're glad to get back to our roots. Why? While QR codes can be helpful, we miss being able to talk about and present our farmhouse ales and wood-fired pizza to our guests in person. We put a lot of love and connection to place into what we do with local grains, wild yeast, and ingredients from Texas farms, and we feel a bit of what makes these things special get lost in the impersonalism of a QR code/screen.

But what about long lines? This was a knock on us prior to QR codes. Today, we're different in that we now run four bars (Pasture, Brewery, Pizzeria, Goat Pen), have our own food truck (JK Kwik Kitchen) to complement our pizza, and can our beer now so we can offer cold cans quickly. Technology has improved too from back when we used to write names and numbers on pizza boxes by hand. We think you'll find our onsite experience for ordering food and drink pretty smooth and fast.

We've always seen Jester King as a beautiful place to enjoy food and drink tied to time, place, and people with friends and family. Ditching screens and connectivity for a bit is something that's part of this. We're happy to be taking a step back in this direction and hope you like it too. Come out and check it out starting this Thursday.

more2023 Star Party at The Hall at Jester King

Our annual Star Party is back!

There are very few places that have dark, open night skies perfect for stargazing and we are happy to be one of them. Join us at The Hall at Jester King on Friday, April 21 from 5:30-10pm alongside the Hill Country Alliance for an evening of observation and exploration into our night sky.

A panel of esteemed voices from the ATX astronomy community will discuss the impact of astronomy in the Hill Country, what observatories in the area have been working on, night sky preservation, and much more! After that, you can stargaze, chat with panelists, browse tables & activities, and check out the planetarium dome from Stars and Science Austin where you can view their Sky Tonight and Losing the Dark programs.

There will be plenty of telescopes to look through with guides to help viewers navigate the night sky, but feel free to BYOT (bring your own telescope)!

We will have food and beer available for purchase.

10% of all ticket sales support Hill Country Alliance. For more information on their amazing organization, please check them out here.

Schedule of events:

- 5:30pm - Doors open

- 5:30pm - Bar opens (beer, cocktails, wine, non-alcoholic beverages)

- 7pm - Panel begins

- 8pm - Stargazing begins

- 10pm - Doors close